1.According to the product type :

According to the principle of motor:it can be divided into explosion-proof asynchronous motor, explosion-proof synchronous motor.

According to the place of use:it can be divided into explosion-proof motors for underground coal mines and explosion-proof motors for factories.

According to the supporting host:it can be divided into explosion-proof motors for coal mine conveyor, explosion-proof motors for coal mine winch, explosion-proof motors for rock loader, explosion-proof motors for coal mine local fan, explosion-proof motors for valves, explosion-proof motors for fans, explosion-proof motors for ship, explosion-proof motors for lifting and metallurgical use of explosion-proof motors, and hydrogenation equipment supporting the use of brushless excitation of the synchronous motor with safety, and so on. In addition, according to the rated voltage, efficiency and other technical indicators, such as high-voltage explosion-proof motors, high-efficiency explosion-proof motors, high-turnover rate explosion-proof motors and high starting torque explosion-proof motors.

- According to product range and its characteristics:

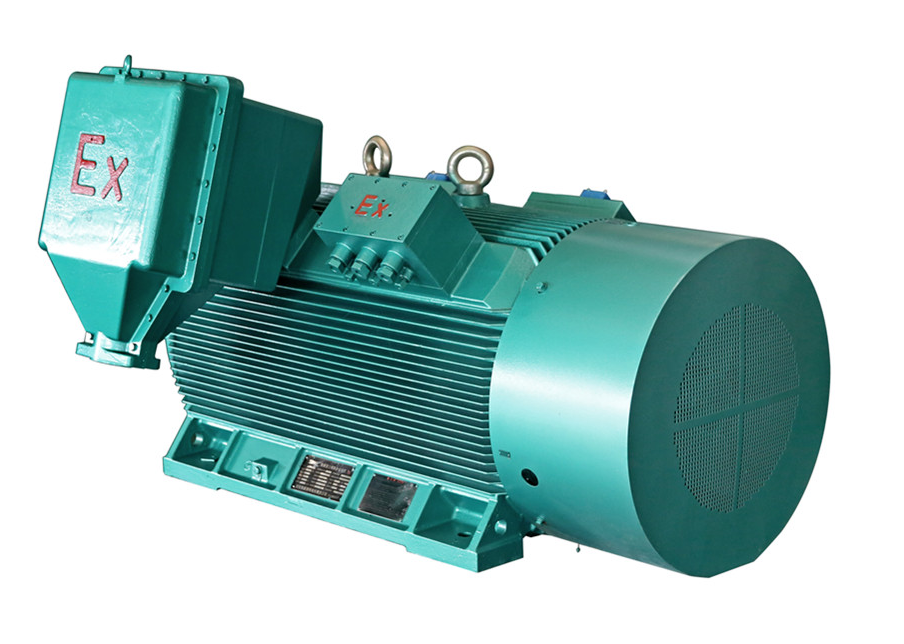

(一)Explosion-proof motors

An explosion-proof housing is used to separate electrical parts that may generate sparks, arcs and dangerous temperatures from the surrounding gas mixture. However, this housing is not hermetically sealed, and the surrounding gas mixture can enter the motor through the gaps in the mating surfaces of each part of the housing. When in contact with the shell of sparks, arcs, dangerous high temperatures and other ignition sources may occur, then the motor of the explosion-proof shell not only will not be damaged or deformed, and flames or hot gases through the gap between the joints, but also can not lead to ignition of the surrounding gas mixture.

Main features:

(1) Correspondence of power level, mounting dimensions and rotational speed is in line with DIN 42673, and necessary adjustments have been made to make it more effective and applicable, taking into account the inheritance with YB series and interchangeability with Y2 series.

(2) The noise limit is lower than that of YB series, close to the class I noise of YB series, and the vibration limit is comparable to that of YB series.

(3) The whole series adopts class F insulation, and the temperature rise is assessed according to class B.

(4) There are two types of motor heat sinks: parallel horizontal distribution and radiation distribution, with parallel horizontal distribution as the main one.

(5) The whole series uses low-noise deep groove ball bearings, and the center height of the seat is 180mm above the motor is equipped with oil injection and discharge device.

(6) Shell protection level increased to IP55.

(7) The main performance indicators to reach the early 1990s international advanced level.

(二) Safety-enhanced motors

On top of the structure of the motor, which does not generate arcs, sparks or dangerous high temperatures under normal operating conditions, mechanical, electrical and thermal protection measures are taken to further avoid the risk of arcs, sparks or high temperatures under normal or recognized overload conditions, thus ensuring its explosion-proof safety.

Main features:

(1) It meets the requirements of explosion-proof motors with increased safety, and adopts a series of reliable measures to prevent sparks, arcs and dangerous high temperatures, so that it can be safely operated in Zone 2 hazardous places.

(2) Adopting brushless excitation, setting rotating rectifier disk and static excitation cabinet, reliable excitation control system; accurate and shockless excitation with down-polarity rotating difference; reliable out-of-step protection of excitation system and strong ability of re-step rectification; reasonable design of line, discharge resistor does not heat up during operation; wide range of excitation current adjustment.

(3) Synchronous machine, AC exciter and rotating rectifier disk are coaxial. The rectifier disk is located between the main motor and the exciter, or placed outside the bearing housing.

(4) The enclosure protection class is IP54.

(5) Adopting class F insulation, temperature rise is assessed according to class B.

(6) Change the traditional lower water cooling to upper water cooling, i.e., the water cooler is placed on the upper part of the motor.

(7) Installation of additional safety type moisture-proof heater, fixed in the cover at the bottom of the motor, used for heating and moisture-proof during shutdown.

(8) Selection of high quality raw materials, electrical and mechanical calculations leave a large margin to meet the operational reliability and the temperature requirements of the safety-enhancing motor.

(9) Setting up perfect monitoring measures; setting up a safety-enhancing self-balancing current transformer for differential protection in the main junction box; burying working and standby platinum RTDs in the stator winding, with the graduation number of Pt100; setting up a leakage monitor to monitor the leakage of the water cooler; setting up a field temperature display instrument and a remote signaling terminal for the two ends of the seated sliding bearings respectively.

(三) Positive pressure motors

Main features:

(1) Configured with a complete ventilation system, with no structural dead space inside the motor that might affect ventilation.

(2) The casing and piping are made of noncombustible materials and have sufficient mechanical strength.

(3) A sufficiently large positive pressure is maintained in the casing and ducting relative to the outside atmosphere.

(4) The motor shall have safety protection devices (such as time relays and flow monitors) to ensure adequate air exchange, there must also be shell air pressure under pressure automatic protection or alarm device.

(5) shell on the open door or cover shall have a power interlocking device. China currently has no unified positive pressure type motor series products.

Post time: Apr-23-2024