When it comes to managing power and controlling the starting and stopping of electric motors, businesses have two popular options: inverters and soft starters. Both devices have their unique features and benefits to meet the needs of different industries. In this article, we explore the differences between inverters and soft starters and help you understand which solution is right for your business needs.

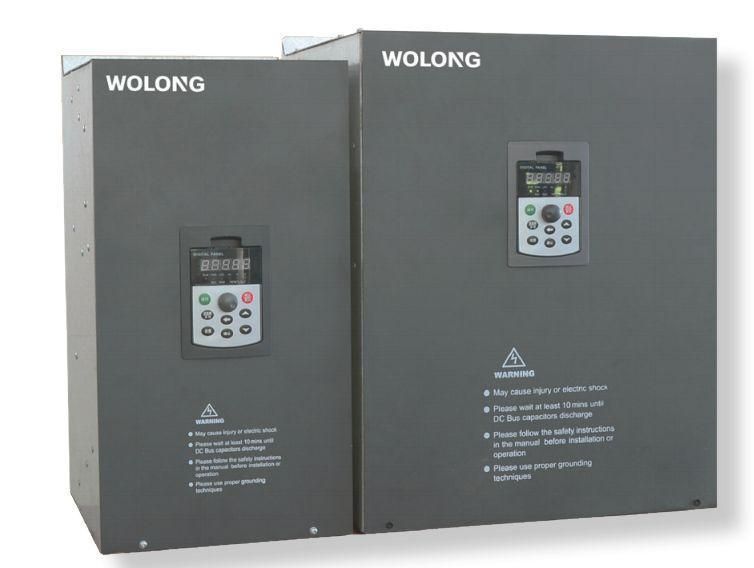

Let's first understand what an inverter and a soft starter are. An inverter, also known as a variable frequency drive (VFD), is an electronic device that varies the frequency and voltage of the motor's power supply. It can precisely control speed and torque, making it ideal for applications requiring adjustable speed and acceleration. A soft starter, on the other hand, is a device that helps a motor start and stop smoothly. It gradually increases or decreases the voltage to the motor to prevent sudden shocks or torque peaks, thereby reducing wear and tear on the motor and connected equipment.

Now that we have a basic understanding of these devices, let's delve a little deeper into their specific applications and benefits. Inverters are widely used in industries that require variable speed control, such as HVAC systems, pumps, compressors, and conveyor belts. By regulating the frequency of electric motors, inverters enable businesses to save energy, optimize performance and reduce mechanical stress on equipment. They also provide additional features such as overcurrent protection, fault diagnostics, and built-in braking.

Soft starters, on the other hand, are mainly used in applications that require reduced voltage starting, such as heavy machinery, crushers, mills, and large centrifugal loads. They help prevent high inrush currents during motor startup that can cause voltage drops and power interruptions. With soft starters, businesses can achieve smooth, controlled starting of electric motors, which prolongs motor life, minimizes maintenance costs and increases reliability.

So how do you decide which solution is right for your business? The answer lies in understanding your specific application requirements. If speed control and energy saving are your main concerns, then an inverter is the best choice for you. The ability to adjust the speed of the motor optimizes performance and energy consumption, ultimately saving money in the long run. On the other hand, if your primary concern is the protection and longevity of the motor and connected equipment, then a soft starter is a more appropriate choice. A soft starter ensures a smooth start to the motor, reducing stress and extending its life.

It is worth noting that for some applications, a combination of an inverter and a soft starter may be the most efficient solution. For example, in applications that require adjustable speed control during normal motor operation but require soft starts and stops to protect sensitive equipment, integrating the two devices can provide the best of both worlds.

In summary, the choice between an inverter and a soft starter depends on your specific application requirements and priorities. Each device has unique advantages to meet the needs of different industries. Whether your priority is energy savings, motor protection, or a combination of the two, considering the unique features and benefits of inverters and soft starters will help you make informed decisions for your business.

Post time: Jun-29-2023